Professional & Industrial

Portable 3D Scanners

Creaform develops highly accurate industrial 3D scanners.

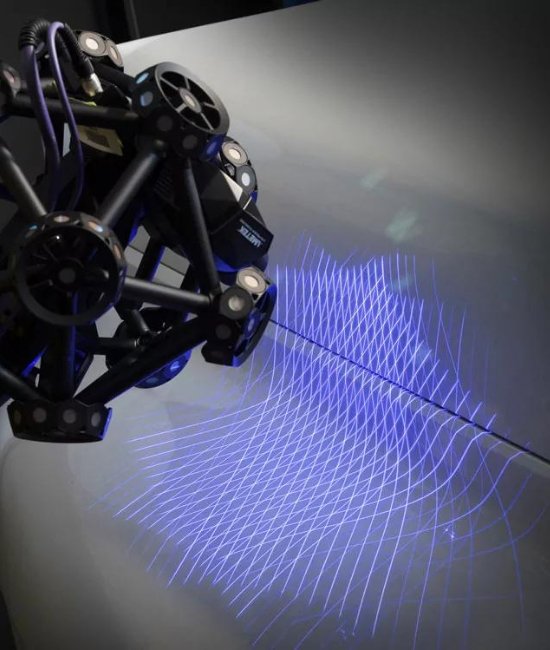

HandySCAN 3D | BLACK Series

Metrology-grade portable 3D scanners

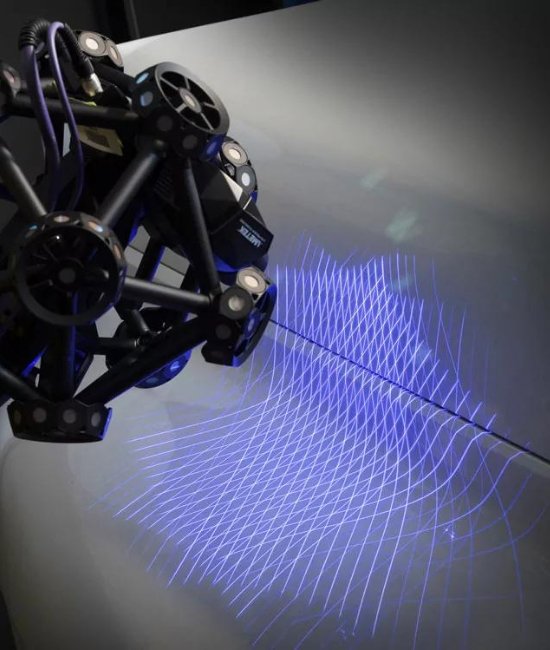

HandySCAN 3D|BLACK Series is the fastest portable metrology-grade 3D laser scanner on the market, offering the highest measurement rate and accuracy available. It’s ideal for product development and quality control.

-

Accuracy

0.012 mm (0.0005 in)

-

Resolution

0.025 mm

MetraSCAN 3D

-

Accuracy

0.025 mm

-

Resolution

0.025 mm

HandySCAN 3D | MAX Series

-

Accuracy

0.075 mm (0.0030 in)

-

Resolution

0.04 mm (0.0016 in)

HandySCAN 3D | SILVER Series

-

Accuracy

up to 0.030 mm

-

Resolution

0.030mm

Go!SCAN 3D

-

Accuracy

up to0.050 mm

-

Resolution

0.100 mm

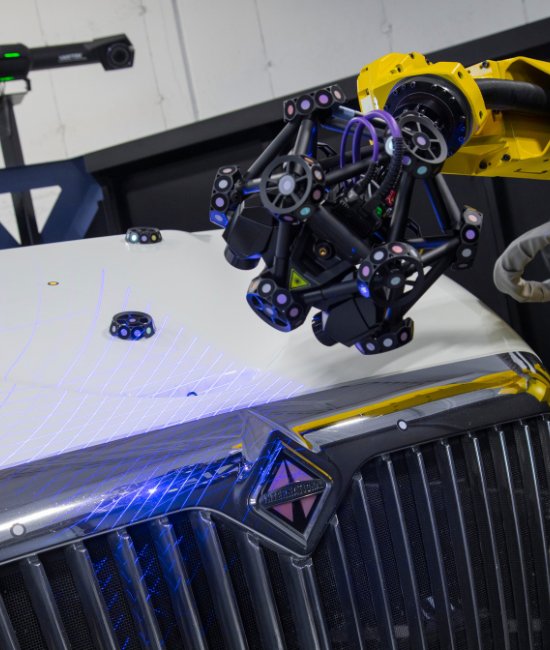

R-Series

Fast and accurate 3D scanning solutions for automated quality control

Detect Quality Issues Faster and Make Better Decisions

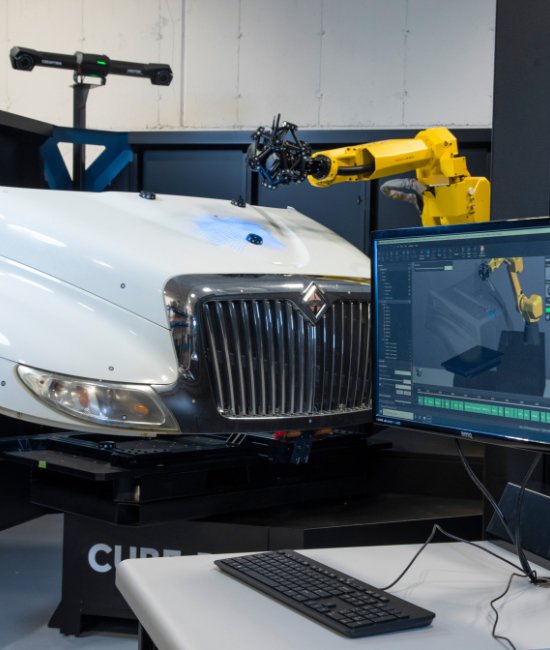

The MetraSCAN 3D-R™ is a powerful, innovative robot-mounted optical CMM scanner that can be seamlessly integrated into automated quality control processes for at-line inspection in mass production. Its cutting-edge technology enables manufacturing companies to detect quality issues faster.

The CUBE-R™ leverages the power of the MetraSCAN 3D-R in a high-productivity industrial measuring cell that has been designed to be integrated into factories for at-line inspections. Compared to traditional CMMs, the CUBE-R is much faster, providing a gain in productivity and better efficiency.

Speed

The MetraSCAN 3D-R enables the measurement of hundreds of parts per day. Perfect for at-line inspection in mass production, it brings quality control as close to the part as possible. From easy integration to quick and simple installation, the MetraSCAN 3D-R helps you speed up your automated quality control processes—and accelerate your time to market.

Accuracy

Up to 3,000,000 measurements/second for short cycle times

Fast measurement speed

Regardless of surfaces, trims, and geometric features

High-density scanning area

69 laser lines

Accuracy and resolution

Due to its metrology-grade accuracy, repeatability, and resolution, the MetraSCAN 3D-R delivers high-quality results, whether on surfaces, trims or geometric features. The MetraSCAN 3D-R is free from rigid measurement setups, making it a 3D scanner engineered for industrial automation in shop-floor conditions. Thanks to the C‑Track optical tracker that enables dynamic referencing, both the 3D scanner and the part can move during inspection—maintaining part alignment as well as measurement accuracy and reliability.

Shop-floor accuracy with dynamic referencing

0.025 mm (0.0009 in) in shop-floor conditions, regardless of instabilities, vibrations, and thermal variations

Reliable acceptance tests

Based on VDI/VDE 2634 Part 3 standard

Based on ISO 10360 standard

ISO/IEC 17025: 2017 accredited laboratory

Volumetric accuracy

0.078 mm (0.0031 in)

High resolution

0.015 mm (0.0006 in)

Versatility

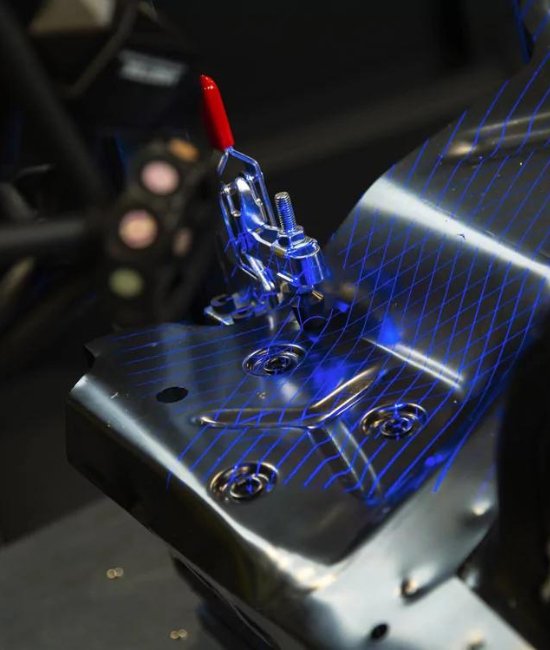

Combining the power of optical and blue laser technologies, the MetraSCAN 3D-R has the capability to generate highly efficient 3D scans on shiny surfaces or on objects with variations in reflectivity as well as measure various part sizes and different surface geometries. The MetraSCAN 3D-R is available as a custom solution with an industrial robot or as a completely turnkey measuring solution with Creaform’s CUBE-R.

Blue laser technology

Ideal for shiny and reflective surfaces

Configurable and customizable portfolio

16 configurations

Large part-size range

Perfect for various part sizes and geometries

Custom integration possible

Operational simplicity

Accessibility to shop-floor operators

No expertise in robotics nor metrology required

Supported robots

Compatible with industrial and collaborative robots

Software independence

Compatible with metrology software

Digital twin environment

VXscan-R scanning intelligence and robot path programming

MetraSCAN 3D-R

MetraSCAN-R BLACK|Elite

Best 3D scanner for parts with a lot of surfaces

The MetraSCAN-R BLACK™|Elite takes 3D scanning to the next level. It incorporates 45 laser lines in a large field of view for fast data acquisition times. The MetraSCAN-R BLACK|Elite is perfect for components with lots of geometries, varying types of materials and finishes, including big castings, large automotive and heavy industries parts or any other complex components or assemblies.

Light source

45 laser lines

Measurement rate

1,800,000 measurements/s

Scanning area

310 x 350 mm (12.2 x 13.8 in)

MetraSCAN-R BLACK|Elite HD

Best 3D scanner for parts with many edges, trims, and boundaries

Based on the same high-performance technology as the MetraSCAN-R BLACK|Elite, the MetraSCAN-R BLACK™|Elite HD features increased resolution to even better address the needs of the automotive market. Designed with an optimized field of view, the MetraSCAN-R BLACK|Elite HD offers increased performance levels in terms of speed and repeatability for challenging applications,such as 3D measurements on sheet metal parts.

Light source

69 laser lines

Measurement rate

3,000,000 measurements/s

Scanning area

190 x 170 mm (7.5 x 6.7 in

CUBE-R

The complete turnkey solution for automated quality control

The CUBE-R leverages the power of the MetraSCAN 3D-R in a high-productivity measuring cell ready to be installed into the manufacturing process. Its robust design is adapted to industrial environments and optimized for shop-floor inspections. VXscan-R’s easy-to-use interface maximizes automatic inspections and minimizes interactions with operators.

Easy to use

Robust design

Optional asset protection

Operating with VXscan-R

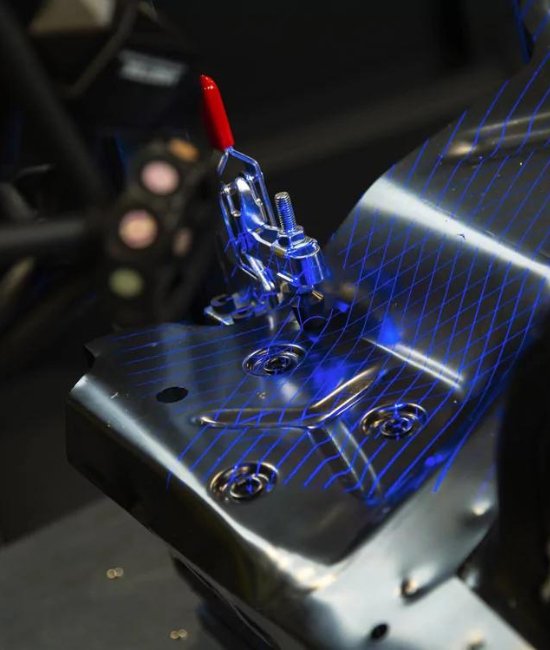

HandyPROBE

Accuracy and simplicity combined with portability

The HandyPROBE is simply the best metrology solution for measuring geometrical entities on parts of any size directly on the production floor.

Achieve Metrology-grade Accuracy

The HandyPROBE is your go-to portable optical CMM to acquire highly accurate, reliable and repeatable 3D measurements—right on the shop floor.

Dynamic referencing

Optical reflectors ensure that accuracy is never compromised because of shop floor conditions.

Reliable acceptance test

The HandyPROBE’s acceptance test follows the ISO 10360-12 standard and is ISO 17025 accredited.

Measure parts with a wide range of sizes

Get accurate measurements of parts ranging from 0.2 to 6 meters (0.7 to 20 feet) in size.

Metrology-grade measurements

Benefit from an accuracy of 0.025 mm (0.0009 in) with a traceable certificate.

Consistent accuracy over time

No accuracy drift over time in your quality control workflows thanks to an easy field calibration procedure.

Take it Anywhere. Use it Anywhere.

Arm-free system

Tackle any inspection, anywhere, with ease thanks to an arm-free system that offers unprecedented freedom of movement.

Versatile measurement capabilities

Measure objects of any size or geometry with confidence.

Take it anywhere

The system, tripod and accessories fit into a single, portable carrying case for easy travelling to remote production sites.

Simplicity that Gets the Job Done

Quality control teams rely on the HandyPROBE’s fast setup time and ease of use to quickly carry out mission-critical inspections and accelerate production.

No rigid setup required

The system can be moved freely in a larger and extendable measurement volume and mitigates conventional leapfrog that occurs with traditional portable CMMs.

Automatic alignments

Optical reflectors allow for repetitive inspections without bogging down processes with realignment.

User-friendly design

The ergonomic wireless probe and multi-function buttons make for faster onboarding and easier interaction with the system.

Optional 3D scanning capabilities by adding the MetraSCAN 3D

MaxSHOT 3D

Elevate your measurement speed and accuracy on large parts

What’s more, thanks to sophisticated, proven user guidance technology and easy-to-use software, technicians of all levels—even non-metrology experts— can use the MaxSHOT 3D. Contrary to traditional photogrammetry, the MaxSHOT 3D features automatic feedback before final measurements captured. Never take a bad image again!

If you consistently work on large-scale projects, the MaxSHOT 3D is your go-to solution to slash budgetbusting measurement mistakes, improve product quality, increase process efficiency, and minimize overall operating costs.

Accuracy

The MaxSHOT 3D enables unprecedented accurate, repeatable and reliable 3D measurements on large-sized parts in a wide range of sectors, including aerospace, heavy industry, power generation and transportation.

Volumetric accuracy

0.015 mm/m (0.00018 in/ft)

Average deviation

0.005 mm/m (0.00006 in/ft)

Reliable acceptance tests

Get accurate measurements of parts ranging from 0.2 to 6 meters (0.7 to 20 feet) in size.

Simplicity

Intuitive software diagnostic tools

Laser projected frame with GO/NO-GO real-time feedback on measurement pictures

Multi-function buttons for easy interaction with VXelements software

Intuitive controls and operations

Experience ultra‑short training and learning curves

Portability

Lightweight and small

0.79 kg (1.75 lb)

Everything in one case

Quick set-up

Up and running in less than 2 minutes

Rugged and robust

Which portable 3D

scanner is right for you?

No matter what type of industrial 3D scanner you are looking for, Creaform has the widest breadth of

3D measurement technologies for any workflow or project. Easy to use, they deliver unmatched performance.

HandySCAN 3D HandySCAN 3DMAX Series |

HandySCAN 3D HandySCAN 3DBLACK Series |

HandySCAN 3D HandySCAN 3DSILVER Series |

Go!SCAN 3D Go!SCAN 3D |

MetraSCAN 3D MetraSCAN 3D |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Accuracy | Up to 0.075 mm(0.0030 in) | 0.012 mm(0.0005 in) | Up to 0.030 mm(0.0012 in) | Up to 0.050 mm(0.0020 in) | 0.025 mm (0.0009 in) | |||||

| Probing | X | |||||||||

| Color Acquisition | X | |||||||||

| Light Source | 38 blue laser lines | 30 blue laser lines | 14 blue laser lines | White light (99 stripes) | 30 blue laser lines | |||||

| Accreditation | ISO 17025 | ISO 17025 | ISO 17025 | |||||||

| Price | + + + | + + + | + | + + | + + + + | |||||

| View the full specs | View the full specs | View the full specs | View the full specs | View the full specs |

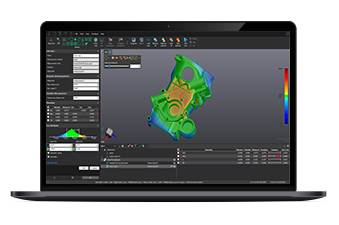

VXelements software platform

3D scanners and 3D measurement technologies. It offers all the essential tools in a user-friendly environment for

real-time visualization and complete 3D scanning experience.

VXinspect™